The Brinell hardness testing is based on uses the outdated system, which is mostly utilized nowadays. This test is frequently applied to control the stiffness of moldings and forgings whose particle arrangement results in perfect testers.

Have the various capacity and bead linkage of trying permitting nearly totally sheets capable of being verified by Brinell test method by purely fluctuating the sheet shape and examining strength established on the taster’s measurement and scheme.

However, most of the time, the sheet shape and strength ratio is always persistent; thus, the outcomes are deliberated perfectly.

The outcomes are always applied widely in manufacturing companies to recognize commercial consignments and excellence regulation dedications.

These outcomes can be similar to numerous metal features like durability, malleability, and flexibility.

Our samples can tolerate threatening atmospheric conditions due to their wind purification structure to guard the internal parts from destruction.

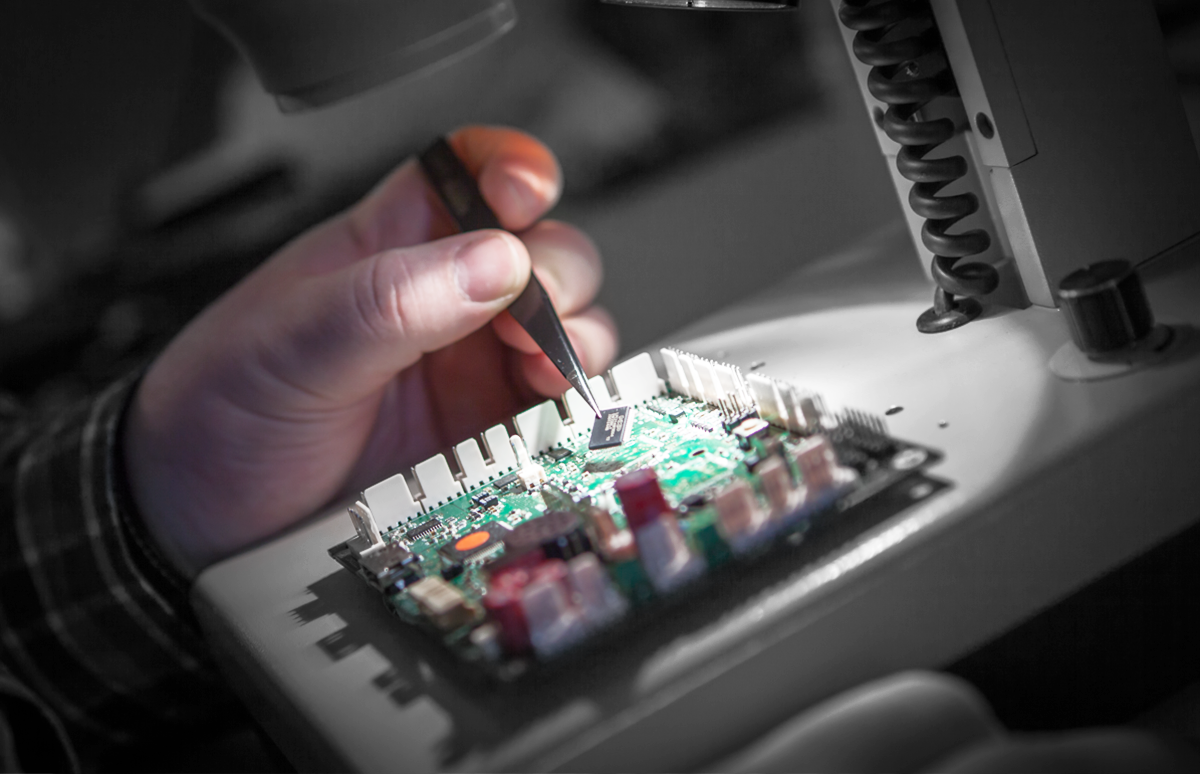

Brinell impression

Impressed for Brinell hardness testing strong copy and effort tributary regulate offers almost eternal significance. Broad-minded processes for pockmark sliding making convention of the latest municipal possessed satisfactory art talents—machine for firmness samples such as stiffness test tool with visible records.

Innovators of hardness testing authorities and the enterprise’s widespread accomplishment providers need the buyer’s evaluations and demands.

Even if they require definite norm demands, we have engineers who will provide dominant purpose clarification.

The old-fashioned standard stiffness models are elaborate automated preparations, made of countless portions and questionable load piles, original individuals founded on weight lockup tools and pack protected twist strength response schemes have reduced these complications of earlier demonstrations.

More Stories

Circular Outdoor Daybed

Review of used diesel engines

Hardness Test Tools from Innovatest