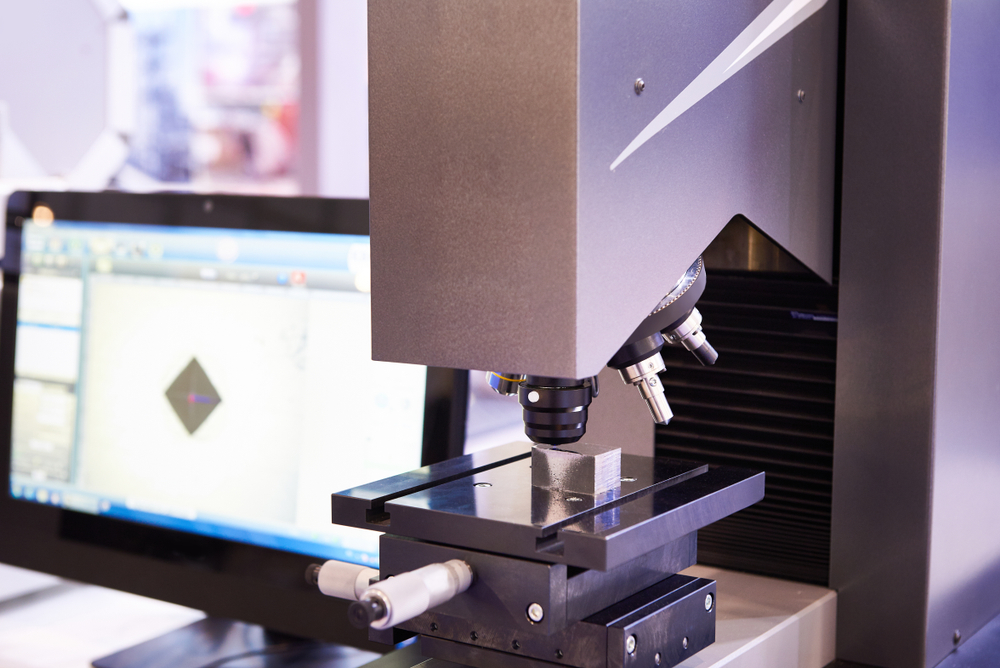

According to ASTM E-18 and ISO 6508, the Rockwell hardness test method is the most commonly used hardness test technique. It is used all over the world to calculate the hardness of a material. It is used to determine the hardness of all metals and, to some extent, also plastics. Rockwell hardness test method measures the permanent depth of indentation that the load on an indenter has produced. It is the easiest and quickest hardness test to carry out because it requires minimal sample prep. This testing method’s major advantage is its speed in testing and its ability to show hardness values directly.

how do hardness test work?

The hardness starts by applying a minor load commonly known as preliminary test force to a sample using either a ball indenter or a diamond. Minor load breakthrough the test sample, and this reduces surface finish effects. Baseline depth is measured after holding a minor load for a set-out time (dwell time).

In the second step, a secondary load known as the major load is added to obtain the required total test load. The major load is then removed, returning to the minor load. The final depth is measured. The hardness value is the measurement change established by the major load from the reference point. The change in distance is then converted to a hardness number.

We manufacture all our components internally, allowing us to have the highest level of quality control in the manufacturing industry.

More Stories